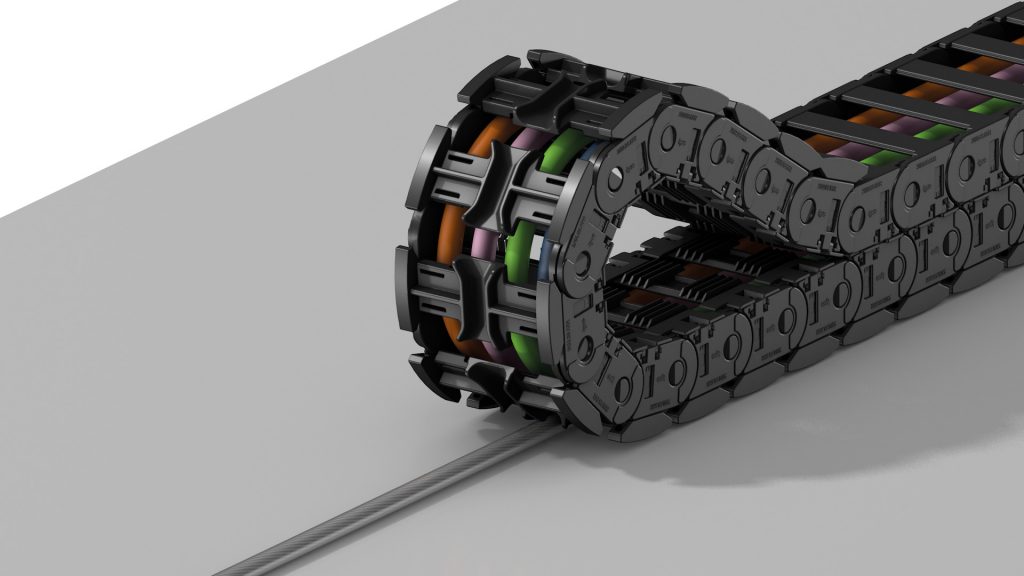

Last week, igus® released hundreds of new products. This happens every year, but this year was slightly different; they were released virtually! Despite not being able to introduce the new products physically, igus® ensured that their customers didn’t miss out and built its own exhibition at their head-office in Cologne. The range of new products has some great cost down, life up benefits! One prime example of this is the new autoglide-5, an alternative to a busbar system. This new system saves 88% assembly time compared to a standard chain and trough combination. This system has been designed to be fitted incredibly quickly as well as being cost effective; approx. 40% cheaper than a standard e-chain® system with guide trough. The key principle is steel which cable keeps the energy chain on track without a need for trough. The funnel shape cut out into the cross bars engages with the steel cable, ensuring surface connection at all times. The system is attached to the floor simply by unrolling the steel cable, bolting it at each end and tensioning it. The chain is then laid onto it. A. Currently the primary model is the 2400 series with 77mm inner width and 75mm bend radius. If you want a different bend radii or width, this is possible on request. A. As this product is brand new the tests are still being run but as with all igus® e-chains® we are aiming for 10 million cycles or 10,000km. If you require test information, this can be supplied on request. A. Absolutely, these are a simple opening cross bar which makes them easy to replace should you need to. A. This is currently being tested in the igus® laboratory so should you wish to look at this option, please contact us! igus® are not only offering the component parts to create your own system but are also offering the autoglide-5 as a harnessed system which includes the e-chain®, cables, hoses, steel rope and connectors, meaning it is ready to fit and use! Customers are already using the autoglide-5 system within their organisations with great success and with the cost saving, ease of installation and the range of applications that the system can be used in, there is no doubt that this will be a very popular system for transmitting your energy, data, liquids and air safely, practically and in a maintenance-free manner!  Perforated Sheet,mini hole perforated metal,diamond hole perforated metal,Oval Shape Perforated Metal Hebei Yingkang Wire Mesh Product Co.Ltd , https://www.wiremesh-china.com

Some key Q&A in relation to this new product:

Q. Which chain type serves as the basis for the new autoglide 5?

Q. Do you know the service life of the autoglide 5?

Q. Can I replace the crossbars if they get damaged or wear out?

Q. Can I use a plastic rope?

hbspt.cta.load(3055426, '98891e85-8a06-4d2f-bc7d-6dfeb4120462', {});

hbspt.cta.load(3055426, '98891e85-8a06-4d2f-bc7d-6dfeb4120462', {});

There are many types and sizes of perforated sheets available, including:

1. Metal Perforated Sheets: These are made from materials like steel, aluminum, stainless steel, and copper. They are commonly used in industries like HVAC, construction, and automotive due to their durability and strength.

2. Plastic Perforated Sheets: Often used in food service, packaging, and construction applications where lightweight and chemical resistance are important.

3. Wooden Perforated Sheets: Used in decorative items, furniture, and acoustic panels where natural wood texture is desired.

4. Rubber Perforated Sheets: Used in industries like automotive, agriculture, and construction where shock absorption, noise reduction, or water drainage are needed.

Perforated sheets can have patterns ranging from simple round holes to complex shapes, and the size and spacing of these holes can vary widely depending on the intended use. They can also be used in both indoor and outdoor applications, and can provide insulation, ventilation, or sound absorption benefits.

Perforated sheet is a type of material that has been punched, drilled, or stamped with holes in a regular pattern. This can be done for various purposes such as allowing air or light to pass through, creating a decorative effect, or providing a non-slip surface.